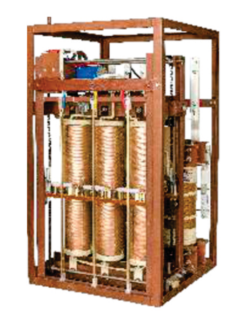

Inner view of automatic voltage controlier unbalance type with ultra isolation Transformer.

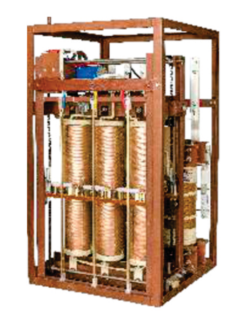

Inner view of Stabillzer (Balanced Type)

High Quality Materials in All Solutions

From small to large elements, we use only the finest materials in our production.

Power & Distribution Transformers 250 KVA to 20 MVA in 11 & 33 KV voltage class,

Transformers were designed and tested as per is : 2026, BS-171, IEC-76, IEC-726 & BIS-1180

Transformers will be connected as per vector group reference Dyn11, Other vector groups can be offered as per specific requirements.

Transformers are designed for a maximum temperature rise of 50/55’C of oil / winding-Lower temperature rise can be offered on request..

H.V.-Bare Bushings or Cable Box, L.V-Bare Bushings or Cable Box. Disconnecting chambers can also be provided on both HV and LV Cable boxes.,

Chemical Earthing electrodes are Earthing electrodes which are used for Earthing

applications in electrical system for Discharge of electrical current to the

ground in case of insulation failure of equipment or fault current in the

electrical system.

This Earthing electrode is used along with the mixture of Bentonite powder

graphite and Carbon which is called chemical earthing or ground enhancement

compound.

The Fault current which arises in the electrical system should be immediately

discharged to the ground safely to avoid any injury or fatal.

Chemical Earthing electrodes are earthing electrodes Manufactured with superior

quality of Mild Steel material which is further coated with zinc coating or

copper bonding.

Chemical Earthing are further classified as Pipe Earthing and solid Earthing

electrode.

Control panels serve as the nerve center of electrical systems, housing components like switches, relays, indicators, and controllers for regulating machinery and ensuring safety. They are vital in industrial settings, like manufacturing facilities and power plants, where precise control is essential.

Modern panels integrate advanced technologies such as PLCs and HMIs for streamlined operations and real-time data visualization. Engineers meticulously design panels, considering factors like functionality, accessibility, and safety, with effective labeling crucial for quick troubleshooting and maximum productivity.

Power factor panels are essential for optimizing electrical system efficiency by addressing power factor issues, which indicate how effectively electrical power is utilized.

A low power factor results in wasted energy and increased utility costs. These panels incorporate capacitors and other devices to improve power factor by adjusting the phase relationship between voltage and current. This minimizes reactive power demand, enhancing overall system efficiency and reducing energy losses.

A transformer with built-in Automatic Voltage Regulation (AVR) represents a compact and efficient solution for voltage control in electrical systems. Combining the functions of a transformer and an AVR into a single unit streamlines installation and maintenance processes, reducing space requirements and enhancing system reliability. This integrated design ensures consistent voltage levels, protecting sensitive equipment from fluctuations and optimizing energy efficiency. Such transformers are particularly valuable in environments where space is limited or where precise voltage control is essential, offering a convenient "two-in-one" solution for power management needs.

In addition to these standard fittings, transformers with built-in Automatic Voltage Regulation (AVR) may incorporate advanced features such as digital displays for real-time voltage monitoring, programmable settings for precise regulation, and surge protection mechanisms to safeguard against voltage spikes.

The integration of these components enhances the functionality and versatility of the transformer, ensuring reliable operation and efficient voltage management in diverse electrical applications.

Dry type transformers are electrical transformers that do not use liquid insulation, such as oil or silicone, for cooling and insulation purposes. Instead, they rely on air or gas to dissipate heat generated during operation. These transformers are typically constructed with high-temperature insulation materials such as epoxy resin or polyester resin, encapsulating the windings and core.

Dry type transformers are commonly used in a variety of applications, including commercial buildings, industrial facilities, renewable energy installations, and transportation infrastructure. They are available in various configurations, sizes, and voltage ratings to meet the specific requirements of different electrical systems.

Dry type transformers offer several advantages over liquid-filled transformers, including: